ThermoMorph Surface

An exploration of future surface fabrication using hybrid materials with different thermo properties. (Tested with PLA and Polyester mesh)

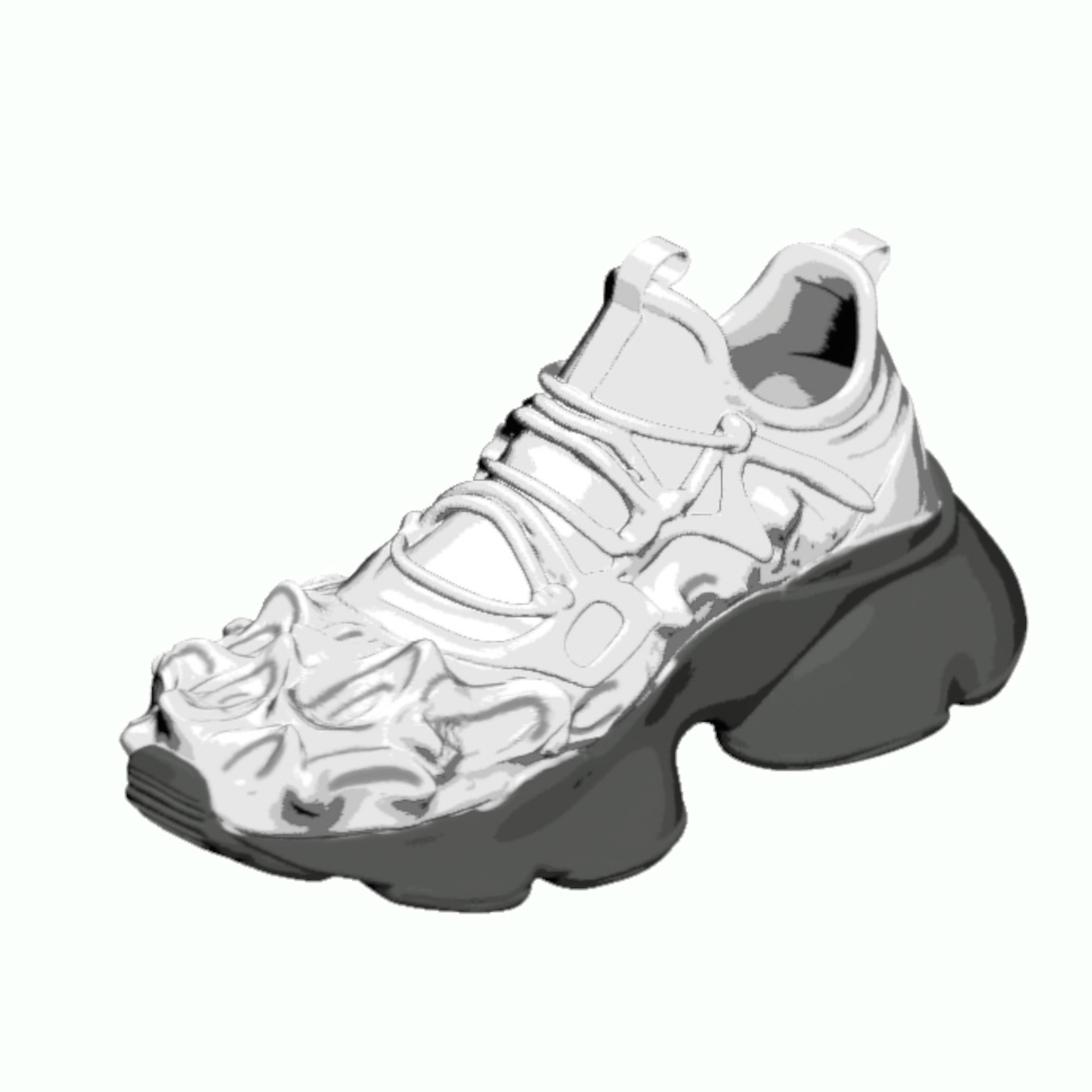

Concept 3D Sketch

Material Tests

Fabrication process

Tool

3D printed heat gun holder attached to UR robot

Robots movements Programming

3D Modeled Textures

Rhino

Sliced for 3D printting

Machine set up

Machine set up

before Heated

After Heated

The polyester mesh base shrinks when heated. In this sample, a heat-reactive PLA is applied; upon heating, the surface texture shifts to yellow and reverts to green as it cools. This color transition visually reveals the thermal responsiveness of the surface.

Test On Sigle Bed Knit Sample

The knitted base made with Puma Stretch yarn shrinks when heated, while the areas reinforced with 3D prints maintain the original loop dimensions.

Application Sketch

Conceptual rendering

Future Application Possibilities

This experiment combines heat-shrinkable polyester mesh with heat-responsive materials. which explores thermally induced structural and color changes.

This approach can be extended to various hybrid material systems for footwear, activewear, or soft surfaces. This enables passive thermal response and localized breathability.

It also opens opportunities for incorporating sustainable materials and low-energy fabrication. These advancements might could shape future functional textile design.